At our facility, we accept properly salted alligator hides only—no whole animals, please. Whether you have a belly skin or a Hornback, we’re here to help turn it into a beautiful leather. Keep in mind that a belly skin is best for products.

Important: Please contact us before bringing or shipping your hide to ensure proper handling and scheduling.

When your hide arrives, you’ll have the opportunity to select your preferred color and finish. We offer a range of options for belly skins, while Hornback finishes are more limited due to the nature of the scales and texture.

Your finished hide is typically ready within 15 to 18 months, depending on the tannery’s schedule. We know it’s a long wait, but this careful process ensures a high-quality, durable result.

The cost of tanning your hide is determined by measuring the widest point of the tanned alligator (in centimeters).

We require a deposit of approximately 50% at the time we receive your hide. The remaining balance will be due upon completion.

Not sure what to make with your finished alligator skins? We can help with that too. Choose from “Our Line” of products or talk to us about custom products.

Please call to see if we are accepting skins before you come.

Please choose an option below.

– Call ahead if dropping off hides (no whole animals)

– We accept hides Monday – Friday: 10am – 12pm & 1pm – 4pm

– All hides must be properly tagged with a CITES tag

– All hides being dropped off must be Skinned, Fleshed, and Heavily Salted

**Extra Charges will be incurred if additional salting or fleshing is required**

– You will need to provide:

– Copy of hunting license -with tag number series visible

– Full contact information (Name, shipping address, phone number and email) for the hunter/hide owner

– Color / Finish Choice

– 50% deposit per hide

– All hides must be properly tagged with a CITES tag

– All hides being dropped off must be Skinned, Fleshed, and Heavily Salted. **Extra Charges will be incurred if additional salting or fleshing is required**

– Make sure they are very well wrapped in multiple bags, to prevent leaking.

– The box should be very sturdy.

– Ship out on Monday or Tuesday to ensure the hides move during the week.

– You will need to provide: Include all contact information (Name, shipping address, phone number and email) with a copy of your hunting license in a Ziplock bag.

– Copy of your hunting license -with tag number series visible

– Color / Finish Choice

– 50% deposit per hide (please call ahead to arrange payment BEFORE shipping)

– Send info & documents to info@markstatonllc.com

Ship to:

Mark Staton, LLC

Attn: Raw Skin Department

111 Bourque Rd.

Lafayette, LA 70506

TAXIDERMY

We do not handle any Taxidermy. If you are interested in “Natural” hides, skulls, or mounts, you can contact a taxidermist of your choice to request instructions for preparation and shipping/delivery.

There is a possibility to do both a leather belly hide and a head from your alligator. This will give you the best of both, but the hide and head must be treated properly.

Cognac Glazed

Gold Glazed

Navy Glazed

Forest Green Glazed

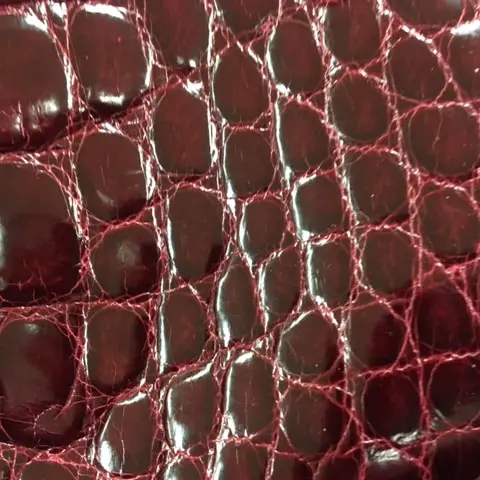

Burgundy Glazed

Red Glazed

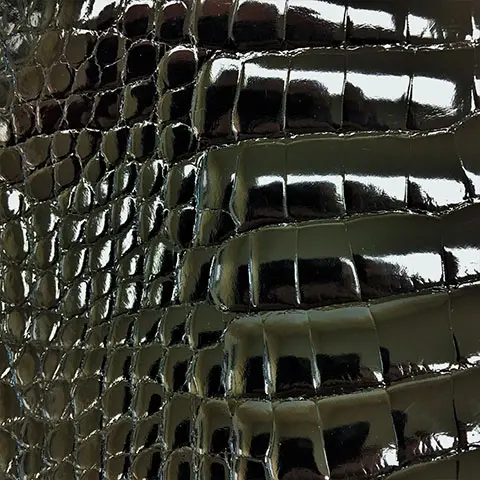

Black Glazed

Brown Glazed

The glazing of alligator and crocodile skins is performed with a special glazing machine. A polished glass or agate cylinder is fast-stroked under high pressure over the surface of the leather after it has been dyed and sprayed with finishing agents. The mirror-like finish results produce the classic shiny appearance of alligator leather goods.

Subject to Dye Lot Variation

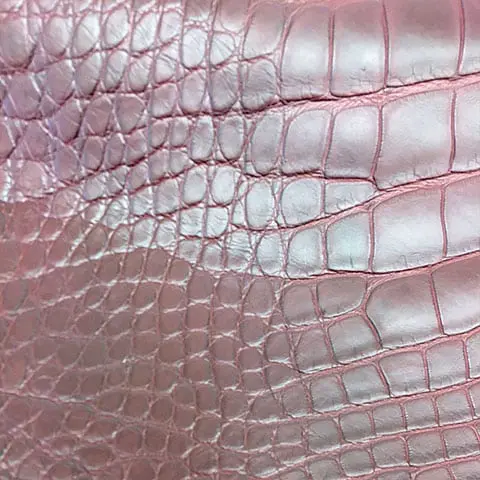

The production of matte finish alligator and crocodile skins does not involve the high-pressure stroking characteristic of the glazing process. Instead, a luster is achieved through buffing and the application of waxes and other finishing agents. This method of finishing, along with techniques such as the addition of oils to the leather and tumbling the skins in drums, produces the soft and supple feel characteristic of matte finish skins. This finish has gained wide acceptance among both manufacturers and consumers of high-quality alligator and crocodile leather goods.

Subject to Dye Lot Variation

Black Matte

Chocolate Brown Matte

Cognac Matte

Gold Matte

Cigar Matte

Almond Matte

Loden Green Matte

Burgundy Matte

Navy Matte

Red Matte